Florida's Premier Epoxy Flooring: Built to Last on the Gulf Coast.

Transform your garage, pool deck, or patio with stunning, low-maintenance concrete coatings engineered to withstand Florida's heat, humidity, and UV rays. Guaranteed.

Licensed & Insured

5 - Year Warranty

Family Owned & Operated

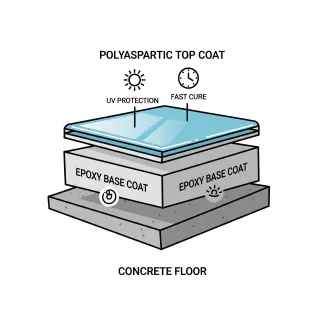

100% Polyaspartic Top Coat

Our Coating Solutions: A Hub for Every Need

The Perfect Coating for Every Florida Surface

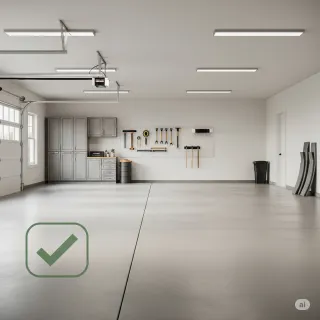

Garage Floors

Transform your garage into a clean, durable, and impressive extension of your home. Our multi-layer systems resist hot-tire pickup, chemical spills from oil and gasoline, and heavy impacts, making cleanup effortless and maintenance a thing of the past.

Pool Decks & Patios

Enjoy a safer, cooler, and more beautiful poolside experience. Our UV-stable, slip-resistant coatings are specifically engineered for Florida's sun and outdoor lifestyle. They stay cooler to the touch than bare concrete and provide essential traction, even when wet.

Sheds & Workshop

Protect your valuable utility space from Florida's pervasive moisture, heavy tool impacts, and stubborn stains. A seamless, waterproof epoxy floor makes any shed or workshop more functional, brighter, and incredibly easy to maintain.

Trailers & Specialty Surfaces

From enclosed race car trailers to commercial utility vehicles, we provide heavy-duty, non-slip surfaces that protect your investment. Our coatings stand up to the toughest use, resisting abrasion, chemicals, and constant wear and tear.

Gulf coast epoxy experts

Our Craftsmanship & Quality Guarantee

We built our reputation along the Gulf Coast on quality that lasts. That's why we guarantee our epoxy flooring against defects in both materials and workmanship. We promise your floor will be installed correctly and professionally, and will not peel or delaminate with normal use. We take pride in our craft, so you can take pride in your floor.

Explore Our Coating Systems

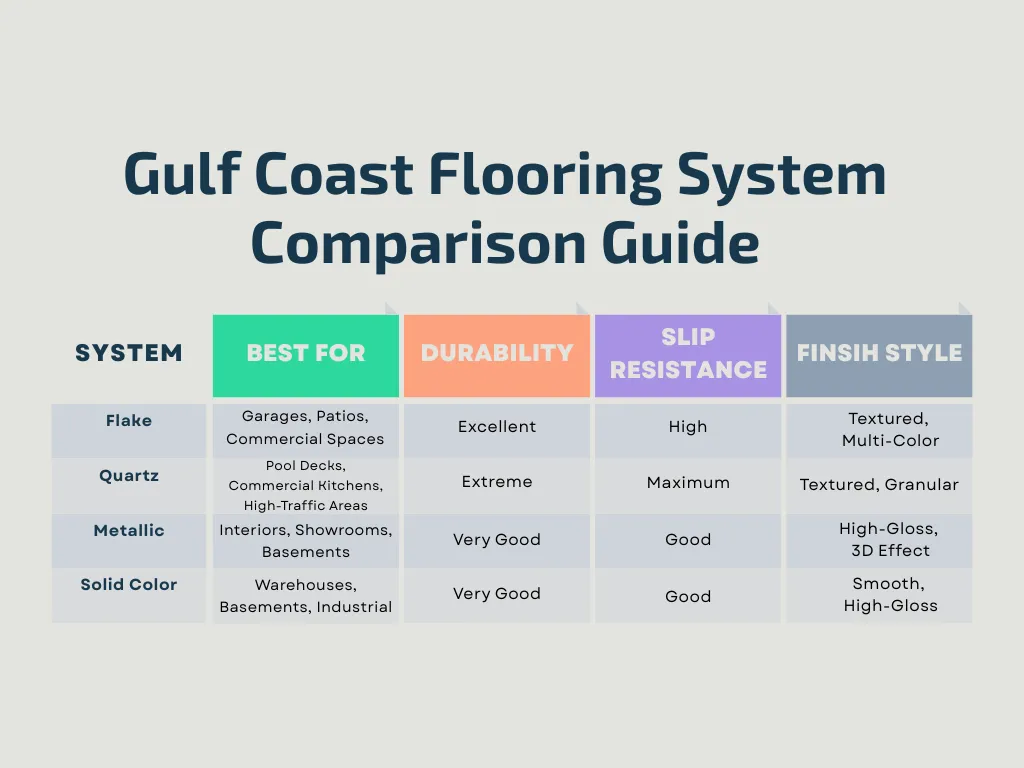

Flake Systems

Our most popular choice for garages and commercial spaces. Multi-layered vinyl flakes are broadcast into the coating to create a vibrant, textured look that is brilliant at hiding minor imperfections in the concrete. This system offers excellent slip resistance and is available in hundreds of color combinations.

Quartz Systems

The ultimate in durability and grip. This double-broadcast system uses colored quartz sand granules to create an incredibly tough, non-slip surface that is ideal for high-traffic commercial areas, wet environments like commercial kitchens, and any space demanding maximum performance.

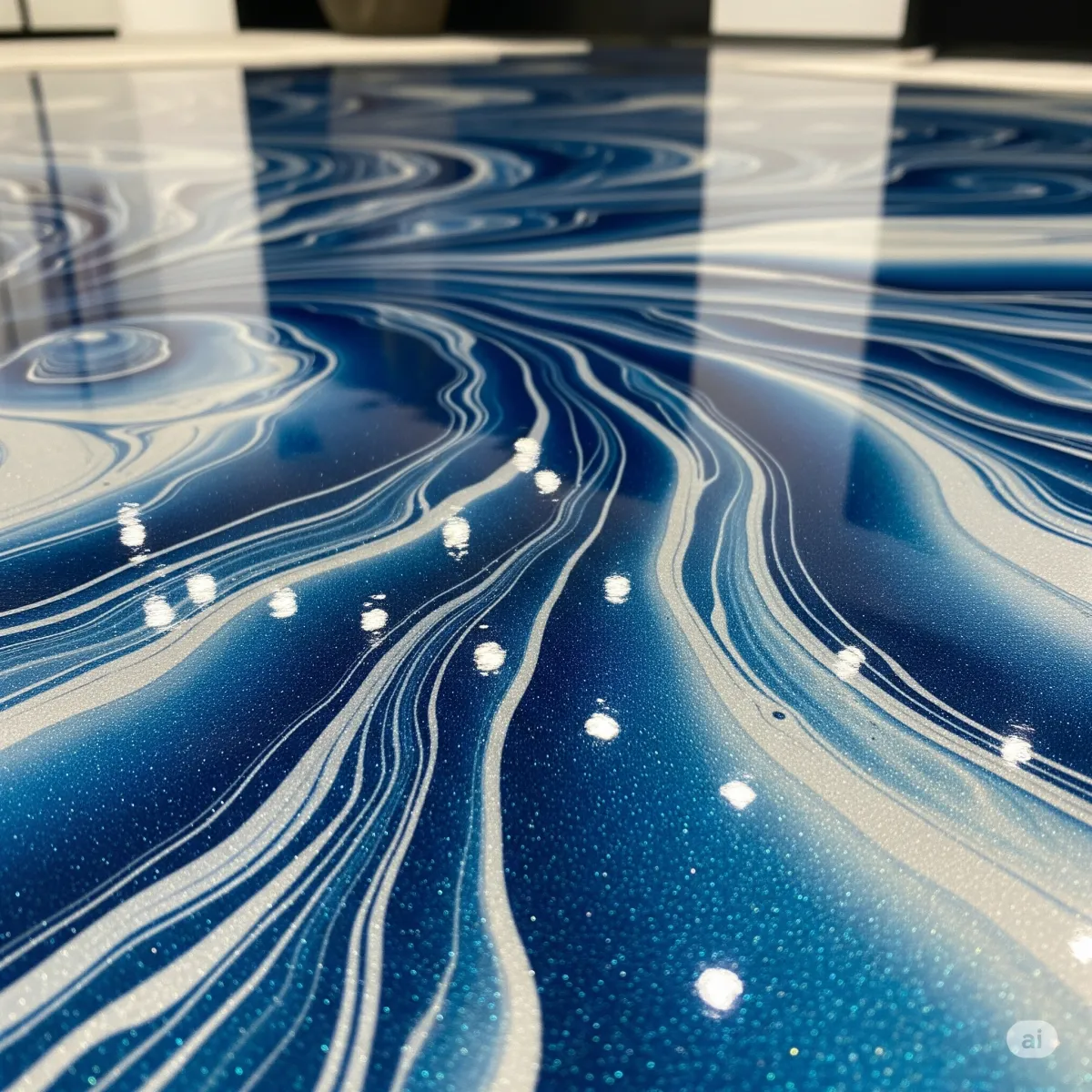

Metallic Systems

A true one-of-a-kind, three-dimensional floor. Special metallic pigments are suspended in 100% solids epoxy and artistically swirled during application to create a stunning, deep, marble or lava flow effect. Every metallic floor is unique, making it perfect for high-end showrooms, modern interiors, and statement rooms.

Solid Color Systems

For a timeless, clean, and professional look. A solid color epoxy provides a sleek, high-gloss, and completely seamless surface. It is an economical yet incredibly durable option for warehouses, basements, and large industrial or commercial spaces where function and cleanability are paramount.

The Gulf Coast Advantage: Why Our Floors Outlast the Rest

Not all epoxy flooring is created equal, especially in a demanding climate like Florida's. While many companies offer what appears to be a similar service, the difference in quality, longevity, and performance lies in the process and the materials. We don't cut corners—we build floors from the ground up with a multi-layer system designed for one thing: unmatched performance and durability on the Gulf Coast. This section explains the critical differences that ensure a Gulf Coast Epoxy Experts floor is a long-term investment, not a short-term fix.

Our Meticulous, Climate-Proof Installation Process

The success or failure of a concrete coating is determined long before the final top coat is applied. Proper surface preparation accounts for up to 80% of a successful installation, and it is the single most important factor in preventing common issues like peeling, bubbling, and delamination, which are rampant in Florida's humid environment. Our process is not just a series of steps; it is a system engineered to create a permanent bond with your concrete.

Step 1: Concrete Profile Grinding: We begin every project by mechanically grinding the entire concrete surface with industrial-grade diamond grinders attached to HEPA-filtered vacuums. This process is virtually dust-free and critically important. It removes any old, failed coatings, sealers, oils, and surface contaminants while opening up the pores of the concrete. This creates a rough, textured profile—similar to 100-grit sandpaper—that allows our primer to penetrate deeply and form an unbreakable mechanical bond.

Step 2: Concrete Repair & Restoration: We meticulously inspect the entire surface for damage. All cracks, spalling (chipping), and divots are repaired using an industrial-grade, fast-curing polyurea mender. This ensures the final surface is perfectly smooth, seamless, and structurally sound.

Step 3: Moisture Vapor Barrier Primer: This is a crucial step that many competitors skip to lower their price, but it is essential in Florida. Concrete is porous and acts like a sponge, constantly wicking moisture from the damp ground below, especially during humid seasons. This upward-moving moisture vapor is the number one cause of coating failure, creating hydrostatic pressure that pushes the coating off the floor from underneath, resulting in bubbles and peeling. We apply a 100% solids, deep-penetrating Moisture Vapor Barrier Epoxy Primer. This specialized primer sinks into the concrete, chemically reacts, and forms a permanent, impermeable barrier that locks out moisture from below, guaranteeing your floor will not delaminate.

Step 4: The Base Coat & System Layer: Once the primer has cured, we apply a thick, 100% solids Polyurethane or Epoxy base coat. This layer provides the floor's foundational strength and serves as the primary color. While this base coat is still wet, your chosen decorative Flake, Quartz, or Metallic accents are broadcast into the resin, creating your unique, custom-designed aesthetic.

Step 5: The Unbeatable Top Coat: The final step is to seal the entire system with a 100% solids Polyaspartic top coat. This is the ultimate protective layer. A polyaspartic coating is chemically different from epoxy; it is 100% UV stable, meaning it will never yellow, fade, or become brittle from exposure to Florida's intense sunlight. It is also more flexible, more scratch-resistant, and offers superior chemical resistance, ensuring your floor remains beautiful and protected for years to come.

Main Headline for Your Offer

Lorem ipsum dolor sit amet, consectetur adipisicing elit.

Benefits you get when joining

Second thing you get instant access to

Third thing you get as a bonus today

CLICK BELOW TO WATCH FIRST!

YOUR NAME, CEO OF COMPANY NAME

Services

Decorative Flake

Create and install custom-designed floor inlays, medallions, and decorative borders made from various flooring materials, adding artistic and unique elements to the floor.

Quartz Broadcast

Offer installation services for radiant floor heating systems, providing energy-efficient and luxurious heating solutions for residential and commercial spaces.

Metallic

Provide installation services for floating cork and wood floors, which offer enhanced insulation, comfort, and versatility.

CUSTOMER REVIEWS

★★★★★

We had a great experience with [Company Name]. They were very helpful in helping us choose the perfect flooring for our home. The installation process was smooth and seamless.

JOHN DOE

★★★★★

We had a great experience with [Company Name]. They were very helpful in helping us choose the perfect flooring for our home. The installation process was smooth and seamless.

JOHN DOE

★★★★★

We were so impressed with the quality of workmanship and customer service we received from [Company Name]. Our new floors look amazing.

JANE DOE

★★★★★

We were so impressed with the quality of workmanship and customer service we received from [Company Name]. Our new floors look amazing.

JANE DOE

FAQS

About Our Flooring & Services

What is the difference between professional installation and a DIY epoxy kit?

The difference is huge and comes down to two key things: preparation and materials. DIY kits use lower-grade, water-based epoxies and can't include the industrial equipment needed for proper surface prep. We use professional diamond grinders to create an ideal surface profile for bonding. Our 100% solids epoxy and polyaspartic materials are significantly thicker, stronger, and more durable than anything sold in a kit, ensuring a floor that won't peel or fail.

What's the difference between an epoxy and a polyaspartic coating?

They work together as a powerful team. Epoxy is known for its incredible thickness and bonding strength, making it a fantastic base coat. Polyaspartic coatings are a newer technology, often used for top coats because they are more flexible, cure faster, and are 100% UV stable—meaning they will not yellow or fade in the Florida sun. We use the best combination of products for a perfect, long-lasting floor.

Can you install epoxy flooring outdoors?

Yes! Using a UV-stable polyaspartic top coat is perfect for outdoor spaces like patios, lanais, and pool decks. We also include an anti-slip aggregate in the top coat for these areas to ensure a safe, textured surface even when wet.

The Installation Process

How long does the installation take?

Most standard residential projects, like a 2-car garage, are completed in just 1 to 2 days. Your floor will be ready for light foot traffic 24 hours after we're done and ready for vehicles and heavy furniture after 72 hours.

What do I need to do to prepare my space?

All we ask is that you clear all items from the floor surface before our team arrives. We handle everything else, from minor crack repair to the crucial diamond-grinding preparation. (Unless you'd like our help, at an additional cost)

Is the process messy or does it create a lot of dust?

Not at all. We take great pride in protecting your property. Our industrial grinding machines are connected to powerful HEPA vacuum systems that capture over 95% of all airborne dust, keeping your home and belongings clean.

Durability & Maintenance

How long will my new floor last?

Not at all. We take great pride in protecting your property. Our industrial grinding machines are connected to powerful HEPA vacuum systems that capture over 95% of all airborne dust, keeping your home and belongings clean.

Are epoxy floors slippery?

While they have a beautiful sheen, they are generally no more slippery than regular tile. For areas prone to moisture like pool decks, garages, or walkways, we always incorporate an anti-slip additive into the final top coat for added safety and peace of mind.

How do I clean and maintain my new floor?

It's incredibly easy. Spills can be wiped up with a simple paper towel. For general cleaning, a dust mop or broom works perfectly. For a deeper clean, you only need a microfiber mop and a pH-neutral cleaner (like diluted Simple Green or ammonia). There's no need for waxing or harsh chemicals.

Cost & Warranty

How much does a professional epoxy floor cost?

The price depends on the size of your space (square footage), the condition of your existing concrete, and the specific system you choose (e.g., Standard Flake, Metallic, Quartz). The best way to get an accurate price is to schedule a free, no-obligation estimate. We'll measure your space, assess the concrete, and provide you with a detailed, all-inclusive quote.

What kind of warranty do you offer?

We proudly stand behind our work with our Craftsmanship & Quality Guarantee. This protects your investment against issues like peeling or delamination resulting from application error. We provide full warranty details with every quote.

Have Another Question?

Our team is ready to help. Contact us today for a free consultation and let's talk about your project!